SHIP INTERIOR SOLUTIONS

RENOTECH DGG

Moisture and mold resistant, incombustible gypsum sheets for ship interiors

PRODUCT OVERVIEW

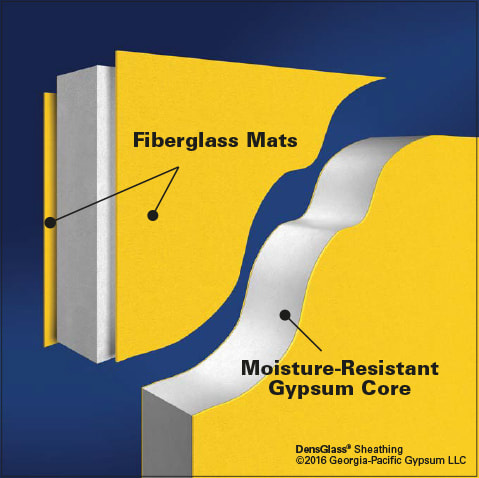

Renotech DGG (DensGlass®) is an incombustible, moisture and mold resistant, reinforced gypsum board for shipbuilding. Renotech DGG gypsum sheathing is MED approved.

KEY BENEFITS

When tested, as manufactured, in accordance with ASTM D3273, Renotech DGG has scored a 10, the highest level of performance for mold resistance under the ASTM

D3273 test method.

When properly used with good design, handling and construction practices, Renotech DGG gypsum board provides increased mold resistance, compared to standard paper-faced wallboard.

Renotech DGG (DensGlass®) is an incombustible, moisture and mold resistant, reinforced gypsum board for shipbuilding. Renotech DGG gypsum sheathing is MED approved.

KEY BENEFITS

- Fiberglass mats eliminate a potential food source for mold and may reduce remediation and scheduling delays associated with paper-faced drywall.

- Replaces traditional paper-faced sheathing.

- Backed with a limited warranty against delamination and deterioration for up to 12 months of exposure to normal weather conditions.*

When tested, as manufactured, in accordance with ASTM D3273, Renotech DGG has scored a 10, the highest level of performance for mold resistance under the ASTM

D3273 test method.

When properly used with good design, handling and construction practices, Renotech DGG gypsum board provides increased mold resistance, compared to standard paper-faced wallboard.

SIZES AND DIMENSIONS

Thickness: 12,7 mm and 15,9 mm.

Dimensions: 1219 x 2438 mm.

TYPICAL USE

Renotech DGG gypsum sheathing is MED approved. It is suitable for shipbuilding, in all interior ceiling and wall applications.

Thickness: 12,7 mm and 15,9 mm.

Dimensions: 1219 x 2438 mm.

TYPICAL USE

Renotech DGG gypsum sheathing is MED approved. It is suitable for shipbuilding, in all interior ceiling and wall applications.

- Walls and ceilings in humid areas: DGG gypsum sheathing integrates a moisture resistant treated core and the yellow glass fiber face is impregnated with anti-mold agent.

- Ceilings, soffits and other ceiling elements: DGG gypsum board is extremely resistant to rippling, buckling and sagging, even under humid conditions.

- Curved wall elements: DGG board can be slightly bent in order to create curved interior elements on board (see Physical Properties - Bending radius).

INSTALLING AND HANDLING

Renotech DGG gypsum sheathing is lightweight and easy to handle. It can be cut and fastened with standard drywall tools and fasteners. The product is much easier to work with than cement board, fiber cement sheathing or magnesium oxide sheathing which tend to be heavy and brittle.

COATINGS

Renotech DGG is an excellent substrate for stucco, plaster or paint finish. Correctly installed and finished assembly surface is seamless and smooth.

Renotech DGG gypsum sheathing is lightweight and easy to handle. It can be cut and fastened with standard drywall tools and fasteners. The product is much easier to work with than cement board, fiber cement sheathing or magnesium oxide sheathing which tend to be heavy and brittle.

COATINGS

Renotech DGG is an excellent substrate for stucco, plaster or paint finish. Correctly installed and finished assembly surface is seamless and smooth.

PROPERTIES

BOARD THICKNESS: |

DGG – 12,7 mm |

DGG – 15,9 mm |

Width, nominal |

1219 mm (± 3 mm) |

1219 mm (± 3 mm) |

Length, standard |

2438 mm (± 6 mm) |

2438 mm (± 6 mm) |

Weight, nominal |

9 kg/m² |

12 kg/m² |

Bending radius ⁵ (lengthwise) |

1829 mm |

2438 mm |

Racking strength (dry) ⁶ (Ultimate – not design value) |

7878 N/m |

9544 N/m |

Flexural strength, parallel ¹ ⁴ |

356 N |

445 N |

Compressive strength |

3445 kPa |

3445 kPa |

Humidified deflection ¹ ⁴ |

6 mm |

3 mm |

Permeance ² |

1300 ng/Pa•s•m² |

970 ng/Pa•s•m² |

R Value ³ |

0,099 m²•K/W |

0,118 m²•K/W |

Combustibility ⁷ |

Noncombustible |

Noncombustible |

Linear expansion ⁸ (with moisture change) |

6,25 x 10⁻⁶ mm/mm %RH |

6,25 x 10⁻⁶ mm/mm %RH |

Flame spread/smoke developed (per ASTM E84 tai CAN/ULC-S102) |

0/0 |

0/0 |

Coefficient of thermal expansion ⁹ |

15,3 x 10⁻⁶ |

15,3 x 10⁻⁶ |

|

¹ Tested in accordance with ASTM C473

² Tested in accordance with ASTM E96 (dry cup method) ³ Tested in accordance with ASTM C518 (heat flow meter) ⁴ Specified values per ASTM C1177 |

⁵ Double fasteners on ends as needed

⁶ Tested in accordance with ASTM E72 ⁷ As defined and tested in accordance with ASTM E136 or CAN/ULC S114 ⁸ As stated by Gypsum Association GA-235 ⁹ Tested in accordance with ASTM E228-85 |

STORAGE AND HANDLING

Renotech DGG gypsum sheets are delivered in bundles, marked with MED approval and the brand name. The plastic wrapping is intended to provide temporary protection from moisture exposure during transit only and is not intended to provide protection during storage after delivery. The wrapping should be removed immediately upon receipt of the shipment.

Store the gypsum sheets in a dry area, on pallets, protected from weather, direct sunlight exposure, and condensation. Keep the gypsum boards neatly stacked flat, in order to prevent sagging or damage to edges, ends and surfaces. Do not stack the DGG gypsum boards on edge or end: gypsum sheets stacked on edge or end can be unstable and present a serious hazard in the workplace should they accidentally topple.

Refer to Handling Gypsum Panel Products, GA-801, for proper storage and handling requirements.

Reference: Application and Finishing of Gypsum Panel Products, GA-216, Gypsum Association.

Renotech DGG gypsum sheets are delivered in bundles, marked with MED approval and the brand name. The plastic wrapping is intended to provide temporary protection from moisture exposure during transit only and is not intended to provide protection during storage after delivery. The wrapping should be removed immediately upon receipt of the shipment.

Store the gypsum sheets in a dry area, on pallets, protected from weather, direct sunlight exposure, and condensation. Keep the gypsum boards neatly stacked flat, in order to prevent sagging or damage to edges, ends and surfaces. Do not stack the DGG gypsum boards on edge or end: gypsum sheets stacked on edge or end can be unstable and present a serious hazard in the workplace should they accidentally topple.

Refer to Handling Gypsum Panel Products, GA-801, for proper storage and handling requirements.

Reference: Application and Finishing of Gypsum Panel Products, GA-216, Gypsum Association.